TMGT

Elite Member

I built this vac 6years ago, the original build was documented on another site, it served well doing multiple yard cleanups over the years and received a few repairs and upgrades over time.

The blower I used when I built it came from an old Ez-Vac I aquired, it worked well but was worn out and only had a 6in hose, which worked well with the 48" deck but struggled to keep up with the 60" that I started using.

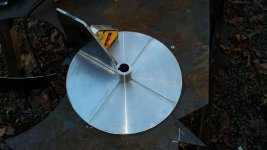

Last year I decided to build a blower from scratch and upgrade to a larger hose and engine while I was at it.

The blower I used when I built it came from an old Ez-Vac I aquired, it worked well but was worn out and only had a 6in hose, which worked well with the 48" deck but struggled to keep up with the 60" that I started using.

Last year I decided to build a blower from scratch and upgrade to a larger hose and engine while I was at it.