richmz

New member

- Joined

- Sep 27, 2020

- Messages

- 8

- Location

- East Central Florida

- Tractor

- JD 790 w/300 Loader, JD Z530M ZTrak

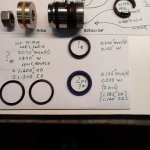

The 300 loader bucket cylinders on my 790 had some leaking going on for a while. One got much worse. I researched rebuilding myself. I've done steering racks before so I opted to tackle this one myself.

My JD dealer about a hour drive away told me the AH176655 seal kit has been superseded to AHC17687. I went there the other day and bought 4 kits, 2 for now, 2 for spares when the boom cylinders act up.

I got the cylinder apart and removed the rod guide inner seal and outer seal. The AHC17687 kit does not have those 2 seals, but several others that don't match any of the seals on either the Bore or the Rod. Earlier today I discovered that the AHC17687 is only for the Bore, and AHC16981 is for the Rod. I ordered 4 of those kits today from HW. hopefully get them by Weds or Thurs.

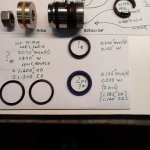

However, can you help me identify what the "?*" seals are in the following diagram? JD Parts website is no help. Maybe they're for other cylinders.

These are plastic, split. Unsure where they fit.

Where would these go?

Thanks,

Rich

My JD dealer about a hour drive away told me the AH176655 seal kit has been superseded to AHC17687. I went there the other day and bought 4 kits, 2 for now, 2 for spares when the boom cylinders act up.

I got the cylinder apart and removed the rod guide inner seal and outer seal. The AHC17687 kit does not have those 2 seals, but several others that don't match any of the seals on either the Bore or the Rod. Earlier today I discovered that the AHC17687 is only for the Bore, and AHC16981 is for the Rod. I ordered 4 of those kits today from HW. hopefully get them by Weds or Thurs.

However, can you help me identify what the "?*" seals are in the following diagram? JD Parts website is no help. Maybe they're for other cylinders.

These are plastic, split. Unsure where they fit.

Where would these go?

Thanks,

Rich