Sleepy Holler John

New member

I have a 2015 JD 3032E and it, up until now was a dud. Back to the dealers at least 12 times before 500 hours, (700 on it now). It was so bad they extended the warrenty to 5 years and 1000 hours, it's up now. In all those repairs I think, (hope) the bugs are worked out.

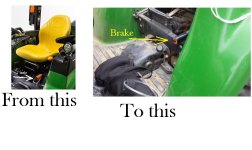

The problem I am having now is one I bet no one else has; it is the design, the design of the hand brake. Here what is going on, I am older, 80+ a little and have old age skin that bruises and tears easily. Every time I get into the tractor the brake handle rips my leg. It sticks out and there is little room getting in. I get partly healed and tear it up again. To add to the problem I have COPD and have to carry oxygen bottles on the tractor. So getting in I am distracted with oxygen hoses and not paying attention to the brake handle. If in the barn I can leave the handle down and the bucket for a brake but only on a flat surface.

Yesterday I decided to alter the handle and was stymied when I looked at it. The handle is fastened to a bracket and the bracket is bolted to the frame with 2 bolts. The handle cannot be removed unless the two bolts are removed, it's riveted. Problem is for me to get to those bolts requires the tire and fender to be removed. I am still looking at a way but it won't be easy, (grind off the rivet but no room). This is so stupid as the shift and brake should have been on the other side allowing more room to get in. What were they thinking???? My beef for the day.

The problem I am having now is one I bet no one else has; it is the design, the design of the hand brake. Here what is going on, I am older, 80+ a little and have old age skin that bruises and tears easily. Every time I get into the tractor the brake handle rips my leg. It sticks out and there is little room getting in. I get partly healed and tear it up again. To add to the problem I have COPD and have to carry oxygen bottles on the tractor. So getting in I am distracted with oxygen hoses and not paying attention to the brake handle. If in the barn I can leave the handle down and the bucket for a brake but only on a flat surface.

Yesterday I decided to alter the handle and was stymied when I looked at it. The handle is fastened to a bracket and the bracket is bolted to the frame with 2 bolts. The handle cannot be removed unless the two bolts are removed, it's riveted. Problem is for me to get to those bolts requires the tire and fender to be removed. I am still looking at a way but it won't be easy, (grind off the rivet but no room). This is so stupid as the shift and brake should have been on the other side allowing more room to get in. What were they thinking???? My beef for the day.