Beaux Duke

Silver Member

My BIL passed away and left me his Lincoln MIG 140 (115v). I realize it's limitations but I'm having fun with it.

My current project is to rebuild the battery tray for my golf cart (inherited that too)

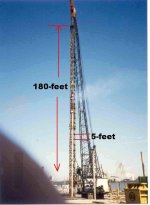

I've finished the tray base and have only the back supporting straps to complete. Lacking metal bending capability I decided to cut the top 4 inches of the existing strap and weld new material to connect the hanger with the tray bottom

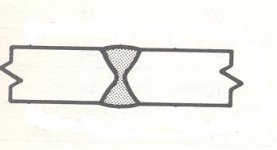

So, what's best? Butt weld the 1/8" by 3" plates or overlap by 1 1/2" or so? Since over 600lbs will be hanging under my tush I want the strongest weld possible.

My welding experience began in hi school AG class and ended when I graduated 2 years later. I know the basics and have been working on test beads for strength and penetration.

I'm considering drilling through the top plate so I can fill in the holes and weld the bottom plate to the top through the holes. I'm open for criticism if it's constructive. Just don't make fun of my welder:soapbox::ambulance:

Thanks

My current project is to rebuild the battery tray for my golf cart (inherited that too)

I've finished the tray base and have only the back supporting straps to complete. Lacking metal bending capability I decided to cut the top 4 inches of the existing strap and weld new material to connect the hanger with the tray bottom

So, what's best? Butt weld the 1/8" by 3" plates or overlap by 1 1/2" or so? Since over 600lbs will be hanging under my tush I want the strongest weld possible.

My welding experience began in hi school AG class and ended when I graduated 2 years later. I know the basics and have been working on test beads for strength and penetration.

I'm considering drilling through the top plate so I can fill in the holes and weld the bottom plate to the top through the holes. I'm open for criticism if it's constructive. Just don't make fun of my welder:soapbox::ambulance:

Thanks