Everhard

Gold Member

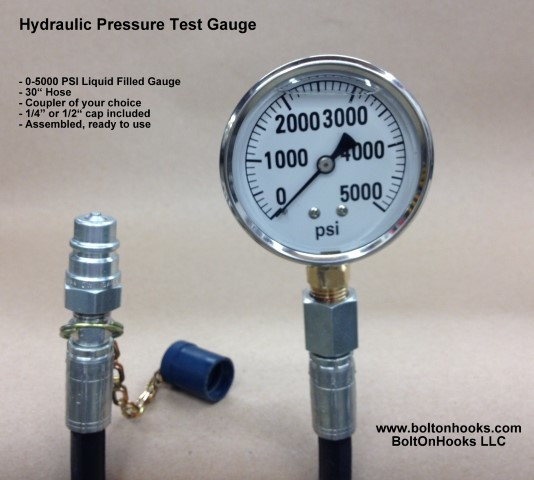

I'm thinking about adding a pressure gauge to my hydraulic system, mostly to make sure it's running at or near the right system pressure for my tractor. I figure if I'm going to test the system I might as well just make the gauge be permanent. So does it matter where the gauge is?

I'd like to put it in line between the loader valve and the custom 3 port valve. (that I added previously which is between the loader valve and the rear hydraulics - rear remote & 3pth.)

Am i right in thinking that will work and the I'll see the system pressure if I T a pressure gauge in on the high pressure line going to the 3 port valve?

Thanks,

E.

I'd like to put it in line between the loader valve and the custom 3 port valve. (that I added previously which is between the loader valve and the rear hydraulics - rear remote & 3pth.)

Am i right in thinking that will work and the I'll see the system pressure if I T a pressure gauge in on the high pressure line going to the 3 port valve?

Thanks,

E.