Aussiebushman

Gold Member

- Joined

- Jul 31, 2008

- Messages

- 252

- Tractor

- Ford 6000

Ok all you "build-your-own" experts - where have I screwed up?

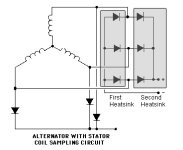

A Marelli (Lucas) 100A alternator was given to a mate (formerly a highly skilled marine electrician) to remove the internal regulator and make up the connections so the field would be activated by a 12V car battery, but the output would be unregulated DC. He seems to have removed the diodes and regulator- see picture.

The basic schematic was the one on the Internet for a Chrysler 120A unit. Power comes from a 5.5Hp 4 stroke petrol engine. The control box contains the wiring from the field via a fuse and switch to the battery. The switch is adouble pole, double throw unit wher one side has a 1 Ohm resistor, the other no resistor. I should actually prefer a rheostat to vary the field and thus the welder amps. The hot wire from the alternator goes though a shunt/meter connection. The negative comes from the alternator frame and there is a Voltmeter across the welding terminals.

First try, there was a pathetic spark at the welding tip. It seemed though the regulator has not been removed. An Ohm-meter reads that one brush is connected directly to the main + terminal with the other brush grounded.

My worry is that if the alternator wiring is wrong, it may dump 100A into the 12V Lead acid battery with potentially disasterous results, even though in theory the fuse would blow.

Where should each of the wires from the brushes go?

Does it appear that the internal rectifier has been eliminated in error?

If so, can I reuse any of the connections that were cut to add an external rectifier and if so, what is recommended?

Alternatively, should I place my head between my knees and kiss my arse goodbye>

Two local auto electricians have virtually refused to help, but I figure someone on this forum can advise - any thoughts appreciated.

Cheers

Alan

A Marelli (Lucas) 100A alternator was given to a mate (formerly a highly skilled marine electrician) to remove the internal regulator and make up the connections so the field would be activated by a 12V car battery, but the output would be unregulated DC. He seems to have removed the diodes and regulator- see picture.

The basic schematic was the one on the Internet for a Chrysler 120A unit. Power comes from a 5.5Hp 4 stroke petrol engine. The control box contains the wiring from the field via a fuse and switch to the battery. The switch is adouble pole, double throw unit wher one side has a 1 Ohm resistor, the other no resistor. I should actually prefer a rheostat to vary the field and thus the welder amps. The hot wire from the alternator goes though a shunt/meter connection. The negative comes from the alternator frame and there is a Voltmeter across the welding terminals.

First try, there was a pathetic spark at the welding tip. It seemed though the regulator has not been removed. An Ohm-meter reads that one brush is connected directly to the main + terminal with the other brush grounded.

My worry is that if the alternator wiring is wrong, it may dump 100A into the 12V Lead acid battery with potentially disasterous results, even though in theory the fuse would blow.

Where should each of the wires from the brushes go?

Does it appear that the internal rectifier has been eliminated in error?

If so, can I reuse any of the connections that were cut to add an external rectifier and if so, what is recommended?

Alternatively, should I place my head between my knees and kiss my arse goodbye>

Two local auto electricians have virtually refused to help, but I figure someone on this forum can advise - any thoughts appreciated.

Cheers

Alan