How about your main hydraulic pressure relief device ? how is your backhoe plumbed ? Dead head on Positive displacement is always bad unless the flow is safely diverted by means of relief device. oil trapped between the gears on your pump have to be able to go somewhere as liq is not compressible. You can dead head a centrifugal pump for a few minutes at most without damage as the impeller can freewheel.

JC,

Thanks JC for responding. Your posts have been very helpful to me in the past. I just tested the pressure with a 0-5000 PSI gauge at the location you showed and it reads zero. You had stated in the other thread 'You might not read pressure there if lift spool valve diverts all the flow back the diffy (highly unlikely)'. I assume this is if you have a defective three point lift, which I was using at the time. But given the sound change of the tractor, 90 seconds or so elapsed time, and a brief smell of a hot something, I'm guessing I damaged the pump.

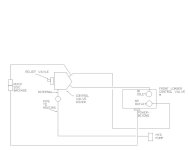

I don't know much about hydraulics, but here is my as-built description of the system. Please correct any incorrect terms I may use. Somehow I think my term 'low pressure return" is inaccurate, but I've attempted to document as best I can.

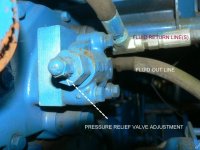

As I show in the photos, it appears to:

1. Leave a high pressure port to the loader valve from under the driver's seat, then returns from the valve to the fitting as noted in the photo.

2. Off of the loader valve, I had installed a 'Power beyond fitting', and this goes to the backhoe, and from there returning to the same return fitting as stated under item 1.

I have read your other post on the pump rebuild, but only maybe 20% of the photos remain in the thread, which is unfortunate.

I will pull it off tonight, and disassemble enough to inspect. They don't show much inside the pump on the parts breakdown. I thought you mentioned you had to buy a seal kit too. From looking at Messicks, I think I need to buy

Object moved

31 SEAL KIT Hydraulic Pump Seal, Interior, See Service Bulletin 3-82, No Exterior Seal Kit Available, Start Year: 01-JAN-79 SBA340490157

1A SEAL PROTECTION Seal, Oil, for Pump Drive Shaft, Start Year: 01-JAN-79 SBA340490151

If it's too wasted, I guess its replacement time. Thanks, Dean