detel

Member

HELP!! I have split my Farm Pro 2430 to replace the clutch. I installed both clutch disks and put everything back together. PTO engages just fine but the drive clutch does nothing. It will grind when I try and put it in gear. I readjusted several times with no luck so I split the tractor today and pulled the clutch pack back out to make sure everything was where it was supposed to be. Installed the clutch pack, married the front and back, adjusted the drive clutch and the same thing, it's like I have no clutch...... I have no clue what I'm screwing up but I would imagine it is something simple!

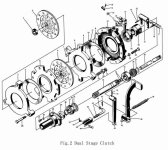

greg-g had posted, "..don't assume the replacement clutchpack will be properly adjusted upon arrival. You should put it on the bench, and start your adjustments there. When the space between clutches is to spec, and the finger heights both to spec AND all equal in height, only then should you bolt it to the flywheel." Can someone please explain to me how you make the adjustments? One thing for sure, it's taken half the time to split it and put it back together then the first time!! :dance1:

greg-g had posted, "..don't assume the replacement clutchpack will be properly adjusted upon arrival. You should put it on the bench, and start your adjustments there. When the space between clutches is to spec, and the finger heights both to spec AND all equal in height, only then should you bolt it to the flywheel." Can someone please explain to me how you make the adjustments? One thing for sure, it's taken half the time to split it and put it back together then the first time!! :dance1: