RalphVa

Super Member

- Joined

- Dec 19, 2003

- Messages

- 7,885

- Location

- Charlottesville, VA, USA

- Tractor

- JD 2025R, previously Gravely 5650 & JD 4010 & JD 1025R

We used the MacKissic TPH-122 A LOT last spring in clearing out piles of debris the May, 2018 storm left down along the creek. Finished off the 2 chipper blades that I'd been swapping back and forth for 15 years and bought a new blade. Then had to get it sharpened (in machine shop). Started off with newly sharpened chipper blade which drew the stuff in nicely but plugged up the chipper discharge to the hammer area just recently. First time I'd ever done that.

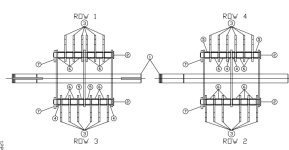

In clearing the blockage, I noticed that I was missing 3 of the 4 grooved pins in the ends of the hammer assembly shafts (part #7 in picture below). Been all week waiting for some new ones from Mac via the local JD dealership. Gave up and went to Lowes and bought some 3/16" roll pins. Too small, and the 1/4" are too big and apparently no 7/32" ones. Hard to put them in, too. The old TroyBilt Tomahawk had them to hold the shafts in, but they were in a position where you could keep some vice grips on them to keep them closed at a 90 degree angle to allow driving them in. Not possible on the Mac.

Cotter pins to the rescue! Bought some 3/16" cotter pins and put them into the holes in the shafts and bent the ends around. We sometimes forget about the old standbys. Had to replace 2 of the grooved pins before getting started and now lost 3 already, but doing A LOT of chipping. Don't think they're a good design, MacKissic. They did design the system well in that it's impossible for the shafts to actually come out, but I had one hit the head on the bolt that holds the access cover for retracting the shafts and broke off about 1/2 the head of the shaft though. None of these 3 with missing pins had done that though.

Ralph

In clearing the blockage, I noticed that I was missing 3 of the 4 grooved pins in the ends of the hammer assembly shafts (part #7 in picture below). Been all week waiting for some new ones from Mac via the local JD dealership. Gave up and went to Lowes and bought some 3/16" roll pins. Too small, and the 1/4" are too big and apparently no 7/32" ones. Hard to put them in, too. The old TroyBilt Tomahawk had them to hold the shafts in, but they were in a position where you could keep some vice grips on them to keep them closed at a 90 degree angle to allow driving them in. Not possible on the Mac.

Cotter pins to the rescue! Bought some 3/16" cotter pins and put them into the holes in the shafts and bent the ends around. We sometimes forget about the old standbys. Had to replace 2 of the grooved pins before getting started and now lost 3 already, but doing A LOT of chipping. Don't think they're a good design, MacKissic. They did design the system well in that it's impossible for the shafts to actually come out, but I had one hit the head on the bolt that holds the access cover for retracting the shafts and broke off about 1/2 the head of the shaft though. None of these 3 with missing pins had done that though.

Ralph