Shield Arc

Super Member

Everyone likes projects, right?:laughing:

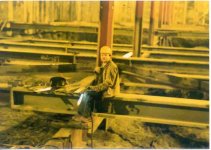

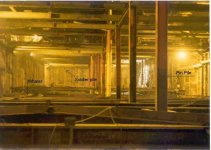

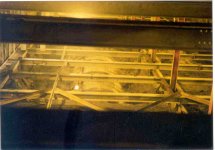

This is the Pioneer Square Station of the Seattle Metro bus tunnel. This station is just over two city blocks long. I forget how deep we had to go . It has 36-inch soldier pile beams drilled and placed every 8-feet on all 4-side of the station. The pavement on 3rd avenue was dug up and removed. We welded 36-inch beams to the soldier pile for a whaler system around the station, then placed the first row of beams in the hole, we used 100-ton jacks to put pressure against the soldier pile so they would not bow in as the dirt was removed. Once the first row of beams were in place. We used 12" x 12" timber mats with expanded metal stapled to them for the cars to drive on. This is called "cut and cover". We put 5-layers of these 14" x 311# wide flange beams. Every day the beams were trucked in from a lay down yard. Crane setting on 3rd avenue would lower them down through a hole in the timber mats. A track loader would grab the beam and drag it to the next location. An excavator would set the beam in place. We had to cut them to length, and weld a plate on the end, and jacking lugs for the 100-ton jacks. Once we had the proper pressure on the jacks, we hard shimmed the beams against the whaler, and welded it. We installed over a million tons of iron in this station.

. It has 36-inch soldier pile beams drilled and placed every 8-feet on all 4-side of the station. The pavement on 3rd avenue was dug up and removed. We welded 36-inch beams to the soldier pile for a whaler system around the station, then placed the first row of beams in the hole, we used 100-ton jacks to put pressure against the soldier pile so they would not bow in as the dirt was removed. Once the first row of beams were in place. We used 12" x 12" timber mats with expanded metal stapled to them for the cars to drive on. This is called "cut and cover". We put 5-layers of these 14" x 311# wide flange beams. Every day the beams were trucked in from a lay down yard. Crane setting on 3rd avenue would lower them down through a hole in the timber mats. A track loader would grab the beam and drag it to the next location. An excavator would set the beam in place. We had to cut them to length, and weld a plate on the end, and jacking lugs for the 100-ton jacks. Once we had the proper pressure on the jacks, we hard shimmed the beams against the whaler, and welded it. We installed over a million tons of iron in this station.

This was a fun project, except for all the mud . The rain water would run down into the station. We would go for months never seeing the tracks on the loader or excavator:shocked:. We tried our best to only walk on the beams, good plan, but didn't always work.:laughing:

. The rain water would run down into the station. We would go for months never seeing the tracks on the loader or excavator:shocked:. We tried our best to only walk on the beams, good plan, but didn't always work.:laughing:

This is the Pioneer Square Station of the Seattle Metro bus tunnel. This station is just over two city blocks long. I forget how deep we had to go

This was a fun project, except for all the mud