vinese

New member

Hi Everyone,

First post so I'll try to keep it brief.

I have a 100 acre parcel of land that is bisected by a swampy little stream bottom. Years back during a dry summer we had gone through the property with a dozer. I'm guessing the operator just pushed some debris into the stream bed and crossed it that way. Several years later all the debris has washed through so now I have no way of accessing approximately 80 Acres of the property.

The stream is probably 5-6ft deep and 8' wide at the point I'm wanting to cross. It's a really slow bayou like stream with fairly level banks on either side. When it floods it just comes of of the banks and spreads..

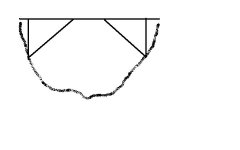

My original Idea was to lay 3 16' treated 6x6's across the stream and use concrete footer pads on each side to rest the beams on. I was going to make it 8' wide and use treated 2x6's as the deck material. To Anchor it I planned on setting 4x4 post in concrete at each corner and attaching it to the bridge to keep the whole thing from floating away during floods.

The primary use of the bride is to cross with ATV's and a 6 seater Polaris Ranger. Secondary use would be to support our 40 hp? New Holland tractor and 6' bush hog so we can occasionally clip the trails.

My Questions is.. After reviewing other peoples bride designs online I see many people using 2x10's or 2x12's 12" OC in lieu of the 6'x6' beams.

I'm curious what load rating would be for the 3 6x6 configuration over the 8' free span would be vs 8 2x10's 12" OC for the same span?

Would either support the weight of the tractor?

First post so I'll try to keep it brief.

I have a 100 acre parcel of land that is bisected by a swampy little stream bottom. Years back during a dry summer we had gone through the property with a dozer. I'm guessing the operator just pushed some debris into the stream bed and crossed it that way. Several years later all the debris has washed through so now I have no way of accessing approximately 80 Acres of the property.

The stream is probably 5-6ft deep and 8' wide at the point I'm wanting to cross. It's a really slow bayou like stream with fairly level banks on either side. When it floods it just comes of of the banks and spreads..

My original Idea was to lay 3 16' treated 6x6's across the stream and use concrete footer pads on each side to rest the beams on. I was going to make it 8' wide and use treated 2x6's as the deck material. To Anchor it I planned on setting 4x4 post in concrete at each corner and attaching it to the bridge to keep the whole thing from floating away during floods.

The primary use of the bride is to cross with ATV's and a 6 seater Polaris Ranger. Secondary use would be to support our 40 hp? New Holland tractor and 6' bush hog so we can occasionally clip the trails.

My Questions is.. After reviewing other peoples bride designs online I see many people using 2x10's or 2x12's 12" OC in lieu of the 6'x6' beams.

I'm curious what load rating would be for the 3 6x6 configuration over the 8' free span would be vs 8 2x10's 12" OC for the same span?

Would either support the weight of the tractor?