I bought a piece of property that has a creek in the front of the property.

There is a wood bridge there now, (20 years old) 7 sets of 5 2"x8"x15' boards bolted together w/ cross boards on top connecting them all and runners on top to drive on.

There is a concrete pad on each side of the creek 2ft thick x 12ft wide x 6' deep.

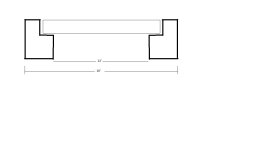

I'd like to replace the wood with 8" or 10" i-beams (as many as it takes) and connect them all with cross boards and runners.

I-beams would be 15' long sitting on the existing concrete pads, concrete pads are 13' apart. so the i-beams would be sitting 1ft of pad on each side. see attached

Does anyone know if this would be strong enough for a single axle dump truck full of gravel?

There is a wood bridge there now, (20 years old) 7 sets of 5 2"x8"x15' boards bolted together w/ cross boards on top connecting them all and runners on top to drive on.

There is a concrete pad on each side of the creek 2ft thick x 12ft wide x 6' deep.

I'd like to replace the wood with 8" or 10" i-beams (as many as it takes) and connect them all with cross boards and runners.

I-beams would be 15' long sitting on the existing concrete pads, concrete pads are 13' apart. so the i-beams would be sitting 1ft of pad on each side. see attached

Does anyone know if this would be strong enough for a single axle dump truck full of gravel?