coachlarry

Member

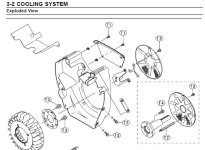

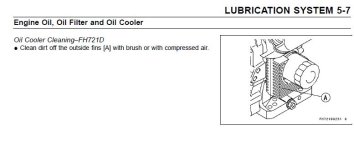

Has anyone successfully modified this engine to have better cooling at the cylinder by the muffler? We live in a warm climate and this head has been fixed a couple times. I bought a salvaged head and replaced it but am looking at the configuration for some mods hat might be interesting. I have a Small mill and lathe at home. The three things that might be changed are the cooling under the shrouds, the location of the muffler, and the valve guides in the head. I was thinking about trying to relocate the muffler

Away from the head or insulate somehow. My other thought is to modify the head. Has anyone used a better valve guide arrangement? Perhaps a different material or threaded guide? Or possibly pin the guide in laterally? Anyway, I am able to do some small machining work so if anyone has a good idea to bullet proof this mower issue please feel free to chime in.

Thanks

Away from the head or insulate somehow. My other thought is to modify the head. Has anyone used a better valve guide arrangement? Perhaps a different material or threaded guide? Or possibly pin the guide in laterally? Anyway, I am able to do some small machining work so if anyone has a good idea to bullet proof this mower issue please feel free to chime in.

Thanks