I have a 310D that I've owned for over 20 years and the backhoe section is getting a little sloppy and it looks like I might need some line boring done. Does anyone have an idea what that would cost per section In other words let's just say for two holes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

310d line bore

- Thread starter bowmanmt

- Start date

- Views: 2284

/ 310d line bore

#1

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,583

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

I've got a 310, and several friends do too. I don't think anyone of us has ever line bored one. If it were me, I'd explore all the other options before line boring. When I think of line boring I think of cannons, not backhoes....  .... BTW, I thought the 310 had replaceable bushings most places, but even gouging and replacing welded bushings would do the job.

.... BTW, I thought the 310 had replaceable bushings most places, but even gouging and replacing welded bushings would do the job.

Those older 310 FELs do have replaceable bushings up front. The parts are cheap, and doing those would be good practice for the hoe job.

I've seen a lot of old 310s wear the pins and bushings because incompatible greases harden like concrete and block the lube channels from the zerks. It can take a torch to melt that grease just to be able to start ot push the bushing out.

Those older 310 FELs do have replaceable bushings up front. The parts are cheap, and doing those would be good practice for the hoe job.

I've seen a lot of old 310s wear the pins and bushings because incompatible greases harden like concrete and block the lube channels from the zerks. It can take a torch to melt that grease just to be able to start ot push the bushing out.

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 2,837

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

This from a machinist friend that does line boring of all types of machines:

"First of all backhoe towers are made out of manganese steel they are not weldable. If you weld on them they get harder than diamond and you can't machine them out. They get brittle and they break if you bore them out and you put a bushing in there it's like a Band-Aid piece upon piece and all the original manganese steel was nasty it lasted a long time the bushings will just mush out he won't be happy. Pretty much as far as cost goes it is pretty much when you show up how dirty it is how wore out they are there's a lot of parameters I can't give you a price per hole"

"First of all backhoe towers are made out of manganese steel they are not weldable. If you weld on them they get harder than diamond and you can't machine them out. They get brittle and they break if you bore them out and you put a bushing in there it's like a Band-Aid piece upon piece and all the original manganese steel was nasty it lasted a long time the bushings will just mush out he won't be happy. Pretty much as far as cost goes it is pretty much when you show up how dirty it is how wore out they are there's a lot of parameters I can't give you a price per hole"

Where do you find this info? Seams very suspect.First of all backhoe towers are made out of manganese steel

You could buy bushing stock and cut off the old holes and weld on new. I did this for a old machine and it was very cheap along with not very laborious.

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 2,837

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

From a machinist that makes his living doing this for a living on excavators, earthmovers and specialty equipment. He had a portable line boring business until California 'outlawed' his diesel truck.Where do you find this info? Seams very suspect.

You could buy bushing stock and cut off the old holes and weld on new. I did this for a old machine and it was very cheap along with not very laborious.

I don't know why you find it suspect as it his professional opinion, but it is only his opinion. In essence, beware and do what you want is the bottom line.

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,583

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

I think your machinist friend must have misunderstood your question.This from a machinist friend that does line boring of all types of machines:

"First of all backhoe towers are made out of manganese steel they are not weldable. If you weld on them they get harder than diamond and you can't machine them out. They get brittle and they break if you bore them out and you put a bushing in there it's like a Band-Aid piece upon piece and all the original manganese steel was nasty it lasted a long time the bushings will just mush out he won't be happy. Pretty much as far as cost goes it is pretty much when you show up how dirty it is how wore out they are there's a lot of parameters I can't give you a price per hole"

I don't know the material composition of backhoe booms, but it is common to weld on them. In fact, if you look at any 310 boom you can see that they are entirely fabricated by welding. Out in the field, serious welding to the boom is typical when mounting a thumb & for other jobs. My JD (yellow) dealer does welding at his shop and so do a number of local portable welders.

Most of the joints on the 310 backhoe and FEL have replaceable pins and bushings from the factory. The bushings don't just "mush out" - they are standard from the factory and last a long time. Replacing them is standard maintenance. JD310s have been built that same way for decades.

Something confusing is I've not heard backhoe & FEL booms called "towers". But the US is a large place; it could be a local term.

I checked in the parts manual when looking up the arms, booms, pins, and bushings.... and couldn't find the anything for towers. I figure on doing some bushing and pin replacements myself on our 310 this year. Closing in on 7000 hrs on the 310, and most of that was demolition & concrete work. So both ends could stand new bushings at least. Hopefully not too many pins.

Machinists generally know their materials. I worked my way through school as a machinist & welder. My guess is that your friend is thinking of something else.

rScotty

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 2,837

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

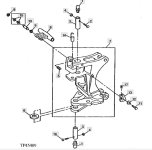

You are right as boom and dipper are formed metal that is welded together with replaceable bushings. The tower or swing frame as Deere calls it (#7 in the illustration) is cast and this is the piece that gets a little slop causing a lot of play down the backhoe. This is the part that would be line bored and bushings installed, if available or procured somehow and the part I asked him about. The tower on older backhoes such as a 310D do not have bushings from the factory installed in them.I think your machinist friend must have misunderstood your question.

I don't know the material composition of backhoe booms, but it is common to weld on them. In fact, if you look at any 310 boom you can see that they are entirely fabricated by welding. Out in the field, serious welding to the boom is typical when mounting a thumb & for other jobs. My JD (yellow) dealer does welding at his shop and so do a number of local portable welders.

Most of the joints on the 310 backhoe and FEL have replaceable pins and bushings from the factory. The bushings don't just "mush out" - they are standard from the factory and last a long time. Replacing them is standard maintenance. JD310s have been built that same way for decades.

Something confusing is I've not heard backhoe & FEL booms called "towers". But the US is a large place; it could be a local term.

I checked in the parts manual when looking up the arms, booms, pins, and bushings.... and couldn't find the anything for towers. I figure on doing some bushing and pin replacements myself on our 310 this year. Closing in on 7000 hrs on the 310, and most of that was demolition & concrete work. So both ends could stand new bushings at least. Hopefully not too many pins.

Machinists generally know their materials. I worked my way through school as a machinist & welder. My guess is that your friend is thinking of something else.

rScotty

The other parts of the hoe with bushings already are pretty obvious that the bushings can be replaced without much trouble and most people would not let them wear to the point that they would wear into the frame. If they did, the hole could be welded and line bored to be refreshed so that a bushing wouldn't mush out.

This is what most people in California refer to as the tower, so it may be a regional term. Anyway, so much for answering the OPs question.

Attachments

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,583

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

Suggest that the OP do his own research on bushings and pins. PDFs of 310 parts manuals are free online

keyword is : Swing frame.

keyword is : Swing frame.

TractorTech

Elite Member

- Joined

- Jan 26, 2012

- Messages

- 2,837

- Location

- California

- Tractor

- Ford 7710, Ford 550, Ford 1910, Ford 4430, KD Forklift, Ford LGT17H, New Holland L255 Skidsteer

Interesting read from a different forum about a swing tower in TN. Also a poster from MA, so I guess not a regional term, rather a Deere term.

Searching Swing Frame or Swimg Tower yields similar results.

Also Wengers and Broken Tractor call it Swing Tower....potAto/potato.

Broken tractor shows a S/N break for bushed towers, but that should be obvious to the owner:

www.brokentractor.com

www.brokentractor.com

Cracked John Deere 310D swing tower

I recently cracked the swing tower on my 1994 John Deere 310 D. I am sure it is Nodular Iron. Is there any chance this can be welded or will it have to be replaced? A new swing tower will cost around $5600 so if it is able to be welded I would prefer that. If this can be welded can anybody...

weldingweb.com

Searching Swing Frame or Swimg Tower yields similar results.

Also Wengers and Broken Tractor call it Swing Tower....potAto/potato.

Broken tractor shows a S/N break for bushed towers, but that should be obvious to the owner:

John Deere Backhoe Swing Tower at Boom Bushing -- T126936

John Deere 310A, 310B, 310C Backhoe Swing Tower at Boom Bushing -- T126936