You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3 point hitch

- Thread starter Duck77

- Start date

- Views: 826

/ 3 point hitch

#1

Vigo327

Platinum Member

Well, there are a couple of things which ‘should’ happen and some other things that shouldn’t.

First, if you have some kind of ‘feedback rod’ from your rockshaft arms to your 3pt lever, it should force the valve handle back to the neutral position when the 3pt hits the top.

2nd, if you hit the top and keep trying to lift, you should be hitting the pressure at which the relief valve opens. When that happens the sound will change (imagine shooting a pressure washer into a pipe) and if so that’s fine and normal, but the engine will still stay under load because it still has to make the power to push X gpm at Y psi. So relief valves do not ‘unload’ the engine, they simply set an upper limit on what the load from the hydraulics can be.

Something that shouldnt happen, is being able to hold the 3pt lever in the raise position and NOT activate the relief valve. If you dont hear any sound change when the 3pt hits the top, your pump may not be able to make enough pressure to hit the factory relief setting. If that’s happening, the next question is, is the 3pt lift strong enough to do what you want? If so, no pressing need to repair even if it WERE low on pressure.

First, if you have some kind of ‘feedback rod’ from your rockshaft arms to your 3pt lever, it should force the valve handle back to the neutral position when the 3pt hits the top.

2nd, if you hit the top and keep trying to lift, you should be hitting the pressure at which the relief valve opens. When that happens the sound will change (imagine shooting a pressure washer into a pipe) and if so that’s fine and normal, but the engine will still stay under load because it still has to make the power to push X gpm at Y psi. So relief valves do not ‘unload’ the engine, they simply set an upper limit on what the load from the hydraulics can be.

Something that shouldnt happen, is being able to hold the 3pt lever in the raise position and NOT activate the relief valve. If you dont hear any sound change when the 3pt hits the top, your pump may not be able to make enough pressure to hit the factory relief setting. If that’s happening, the next question is, is the 3pt lift strong enough to do what you want? If so, no pressing need to repair even if it WERE low on pressure.

Last edited:

Tx Jim

New Member

Welcome to this forumDoes anyone know why my pump stays under a load when my hitch tops out. Seems as if the valve is not bypassing as it should.

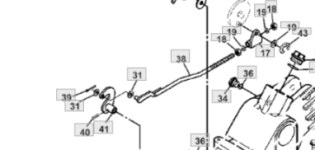

It would help immensely to receive correct answer if you would reveal what machine you're inquiring about. If your question pertains to JD 4200 in your profile then I agree with Vigo that the feedback rod(item 38) on 3 pt control linkage probably needs adjusting.

Attachments

LD1

Epic Contributor

Ditto. Adjust the feedback rod

Dave M7040

Elite Member

- Joined

- Dec 10, 2012

- Messages

- 2,757

- Location

- Williamstown Ontario Canada

- Tractor

- Kubota M7040 Nuffield 465