mercdv

Silver Member

Hey all,

I need some help and I'm hoping this is the place to get it. First, I'd like to start off by saying I have really basic mechanic skills. By basic I mean I can follow service manuals and that is about it. My 2305 sat parked for a long time due to a sick child and back injury. When I started it up last time it ran fine at low idle but when I throttled up it jumped to max RPM's and stayed there. The throttle had no effect and the tractor would not shutoff. It was not increasing RPM's like a runaway but just stuck at max RPM's. I finally got it shutoff by cutting the air supply. I got mad and left it for a long time again and just now getting back to working on it. The fuel solenoid checks out just fine. The throttle didn't seem like it was moving much in the governor so I have removed the governor but here is where I am lost because the manual doesn't say anything about the fuel injection pump and the info I can find on the web doesn't answer my question. So here goes...

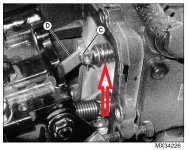

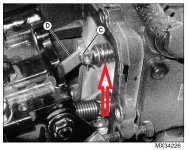

The engine is a Yanmar 3TNV76 in case you need to know. The question I have is in the picture (below) "D" is the governor linkage that attaches the governor to the fuel injection pump with pin "C." Where the linkage connects to the rod and spring coming out of the injection pump (not sure what it is called but it is what the red arrow points to), that was really hard to move to get the linkage apart. Having never worked on one of these before is that rod and spring supposed to slide freely in and out of the pump with very little pressure. I'm assuming it shouldn't take much pressure but I have no idea. If it is supposed to move freely I'm guessing that is my problem since mine doesn't and it seems like that is the only part that doesn't move freely in the governor area that could be stuck to cause the high RPM's. Any thoughts? In the picture that is the governor housing on the left and the fuel injection pump on the right.

Thanks....

I need some help and I'm hoping this is the place to get it. First, I'd like to start off by saying I have really basic mechanic skills. By basic I mean I can follow service manuals and that is about it. My 2305 sat parked for a long time due to a sick child and back injury. When I started it up last time it ran fine at low idle but when I throttled up it jumped to max RPM's and stayed there. The throttle had no effect and the tractor would not shutoff. It was not increasing RPM's like a runaway but just stuck at max RPM's. I finally got it shutoff by cutting the air supply. I got mad and left it for a long time again and just now getting back to working on it. The fuel solenoid checks out just fine. The throttle didn't seem like it was moving much in the governor so I have removed the governor but here is where I am lost because the manual doesn't say anything about the fuel injection pump and the info I can find on the web doesn't answer my question. So here goes...

The engine is a Yanmar 3TNV76 in case you need to know. The question I have is in the picture (below) "D" is the governor linkage that attaches the governor to the fuel injection pump with pin "C." Where the linkage connects to the rod and spring coming out of the injection pump (not sure what it is called but it is what the red arrow points to), that was really hard to move to get the linkage apart. Having never worked on one of these before is that rod and spring supposed to slide freely in and out of the pump with very little pressure. I'm assuming it shouldn't take much pressure but I have no idea. If it is supposed to move freely I'm guessing that is my problem since mine doesn't and it seems like that is the only part that doesn't move freely in the governor area that could be stuck to cause the high RPM's. Any thoughts? In the picture that is the governor housing on the left and the fuel injection pump on the right.

Thanks....