90cummins

Veteran Member

My 1720 started having intermittent issues with grinding months ago when starting in cold weather.

I removed the starter & found no obvious problems but did notice some oil in the solenoid so I cleaned it to eliminate the possibility of that causing slow engagement, I did noticed 3 spots on the flywheel that were taking a beating but nothing serious.

I bought a new solenoid for good measure and installed it and it was fine till a couple weeks ago.

The grinding became serious requiring 2 or 3 attempts to start so I pulled the starter again which looked fine but the flywheel was worse.

I tried to dress a couple teeth but quickly gave up on that.

A new ring gear costs $300 plus 16 to 24 hours of labor so that wasn't going to happen.

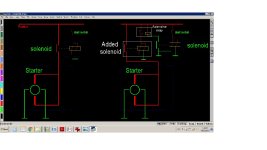

Thinking about the start process I reasoned that if I allowed the starter drive to engage the flywheel before the starter motor started turning I could solve the problem.

What I did was purchase an old 70's style Ford starter solenoid to separate the 2 functions that occur automatically.

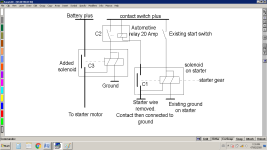

First I removed the battery cables from the starter leaving only the wire that energizes the starter from the key switch, then I spliced into that wire to supply power to a pushbutton switch only when the key was in the crank position.

I then ran another wire from the pushbutton switch to the new solenoid which would then energize the starter motor cranking the engine over.

The battery cables that were removed from starter were connected together along with a new longer battery cable which was attached to the new Ford style solenoid which was mounted on the fire wall.

A new cable from the new solenoid was directly attached to the wire that goes into the starter housing which energizes the starter motor.

A small ground wire was attached to the starter solenoid terminal that formerly had the wire which runs into the starter motor, this is a necessary ground for the solenoid on the starter to function.

This has solved the grinding by allowing the starter drive gear to engage the flywheel before spinning.

The safety interlock's intact preventing starting while in gear.

Currently when I start the engine I engage the starter gear then bump the starter button to ensure the gears are engaged.

Hopefully this will save someone the expense of replacing a flywheel or ring gear.

This should work with any vehicle that has a starter with an integrated solenoid.

Thanks

90cummins

I removed the starter & found no obvious problems but did notice some oil in the solenoid so I cleaned it to eliminate the possibility of that causing slow engagement, I did noticed 3 spots on the flywheel that were taking a beating but nothing serious.

I bought a new solenoid for good measure and installed it and it was fine till a couple weeks ago.

The grinding became serious requiring 2 or 3 attempts to start so I pulled the starter again which looked fine but the flywheel was worse.

I tried to dress a couple teeth but quickly gave up on that.

A new ring gear costs $300 plus 16 to 24 hours of labor so that wasn't going to happen.

Thinking about the start process I reasoned that if I allowed the starter drive to engage the flywheel before the starter motor started turning I could solve the problem.

What I did was purchase an old 70's style Ford starter solenoid to separate the 2 functions that occur automatically.

First I removed the battery cables from the starter leaving only the wire that energizes the starter from the key switch, then I spliced into that wire to supply power to a pushbutton switch only when the key was in the crank position.

I then ran another wire from the pushbutton switch to the new solenoid which would then energize the starter motor cranking the engine over.

The battery cables that were removed from starter were connected together along with a new longer battery cable which was attached to the new Ford style solenoid which was mounted on the fire wall.

A new cable from the new solenoid was directly attached to the wire that goes into the starter housing which energizes the starter motor.

A small ground wire was attached to the starter solenoid terminal that formerly had the wire which runs into the starter motor, this is a necessary ground for the solenoid on the starter to function.

This has solved the grinding by allowing the starter drive gear to engage the flywheel before spinning.

The safety interlock's intact preventing starting while in gear.

Currently when I start the engine I engage the starter gear then bump the starter button to ensure the gears are engaged.

Hopefully this will save someone the expense of replacing a flywheel or ring gear.

This should work with any vehicle that has a starter with an integrated solenoid.

Thanks

90cummins