VTPSD

Bronze Member

- Joined

- Jul 8, 2013

- Messages

- 86

- Location

- Starksboro VT

- Tractor

- ford 420 industrial with custom turbo setup, diesel converted wheel horse

Good Morning,

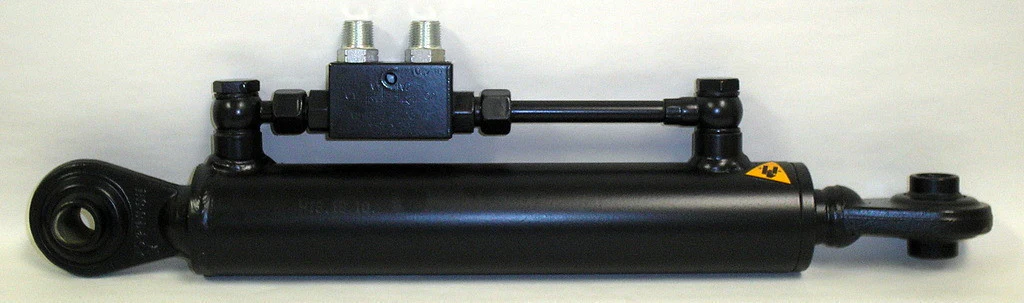

I have a hydraulic top link on my deere 5400. It is similar to what is shown here, but there is about 2-3 more inches of space between the end of the cylinder and the eye on the rod end. I would like it to be about 1.5-2" shorter so I can get a more aggressive angle with my box blade.

I am considering shortening the space between the non-used end of the rod and the eye (so it looks more like the unit shown here). I would be cutting it with a cutoff wheel and welding back on with my miller 211 MIG welder. Is there any reason that I can't do this at home? I think there is enough space on the end of the rod that I would not have to worry about damaged chrome.

I have a hydraulic top link on my deere 5400. It is similar to what is shown here, but there is about 2-3 more inches of space between the end of the cylinder and the eye on the rod end. I would like it to be about 1.5-2" shorter so I can get a more aggressive angle with my box blade.

I am considering shortening the space between the non-used end of the rod and the eye (so it looks more like the unit shown here). I would be cutting it with a cutoff wheel and welding back on with my miller 211 MIG welder. Is there any reason that I can't do this at home? I think there is enough space on the end of the rod that I would not have to worry about damaged chrome.