justractors

Silver Member

- Joined

- Mar 26, 2002

- Messages

- 116

- Location

- Frozen North, Michigan

- Tractor

- Several Antique Garden tractors

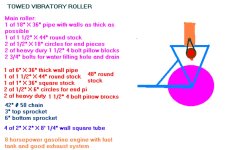

I am considering building a towed vibrating roller for packing a track for pulling Garden Tractors.

I attached a Works drawing of what I have in mind which is a smaller version of a towed unit I saw a a local golf course.

There are a couple of mistakes in the materials list but this is the general idea. I will probably go with a 48" unit instead of the 36" but am concerned with the trailering weight.

Any suggestions would be appreciated.

Thanks,

Bill

I attached a Works drawing of what I have in mind which is a smaller version of a towed unit I saw a a local golf course.

There are a couple of mistakes in the materials list but this is the general idea. I will probably go with a 48" unit instead of the 36" but am concerned with the trailering weight.

Any suggestions would be appreciated.

Thanks,

Bill