SnowRidge

Elite Member

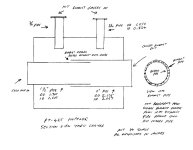

While I had my engine out, I took a close look at the PT built muffler--see attached sketch. I discovered it has a rather restricted outlet diameter--enough so, that I thought it warranted discussion.

I took measurements of the Kohler and the muffler. The Kohler's exhaust ports have an I.D. of 1.04 inches. They appear to be designed to mate up with Sch. 40, 1" pipe, which has an I.D. of 1.049". The muffler's two exhaust port manifold pipes appear to be Sch 40, 3/4" pipe, with an I.D. of 0.824". On mine, the mounting flanges do not align well with the pipe.

The manifold pipes enter the muffler chamber where the gasses are bounced off of some sort of curved deflector (or perhaps the pipes themselves curve inside the chamber).The muffler has a large exhaust pipe constructed of what appears to be Sch. 40, 2" pipe, with an O.D. of 2.375" and an I.D. of 2.067". There is also a cold air intake pipe constructed of what appears to be Sch. 40, 1 1/2" pipe, with an O.D. of 1.900" and an I.D. of 1.610".

The muffler is constructed in such a manner that the cold air intake pipe enters through the left side of the chamber, and is concentric with the exhaust pipe, which exits through the right side of the chamber. In other words, the cold air intake pipe goes into the exhaust pipe. Exhaust enters the exhaust pipe by flowing around the outside of the air intake pipe. That is the only opening into the exhaust pipe, except for the inside of the cold air intake pipe. I hope that makes sense.

My math (always suspect) calculates the following areas:

Kohler exhaust port 0.86 sq. in.

Muffler inlet pipe 0.53

Exhaust outlet pipe (I.D.) 3.36 sq. in.

Cold air inlet pipe (O.D.) 2.84

Effective outlet area 0.52

The effective outlet area is represented by the xxxx's on the sketch.

These numbers concern me. The choking down of the exhaust ports into small diameter pipes doesn't seem like a normal way to design an exhaust system, and while the effective outlet area is only 0.01" less than the choked down exhaust inlet pipes, it still seems awfully small to me.

Beyond the design concerns, there is the manner of actual construction. As I noted earlier, the exhaust mounting flanges are poorly aligned with the 3/4" pipes, which will cause an additional restriction. Worse, the inside end of the cold air intake pipe doesn't look like it was ever cleaned up after being cut and before being welded into place.

The rough edges from the cut clearly increase the O.D. of that pipe, which in turn reduces the effective outlet area. The inside end of the exhaust outlet pipe may well have the same problem, but I have no way of seeing that point without tearing the muffler apart.

The thrust of all this boils down to this: I think these mufflers (at least the one on our PT-425) are choking the Kohler engines, and may be making them run hotter than necessary, and may be reducing available power to a significant degree.

I am seriously considering either modifying the muffler, building an entirely new one along the same design, but with different pipe sizes, or installing a Kohler muffler instead.

So, what do you all think?

SnowRidge

I took measurements of the Kohler and the muffler. The Kohler's exhaust ports have an I.D. of 1.04 inches. They appear to be designed to mate up with Sch. 40, 1" pipe, which has an I.D. of 1.049". The muffler's two exhaust port manifold pipes appear to be Sch 40, 3/4" pipe, with an I.D. of 0.824". On mine, the mounting flanges do not align well with the pipe.

The manifold pipes enter the muffler chamber where the gasses are bounced off of some sort of curved deflector (or perhaps the pipes themselves curve inside the chamber).The muffler has a large exhaust pipe constructed of what appears to be Sch. 40, 2" pipe, with an O.D. of 2.375" and an I.D. of 2.067". There is also a cold air intake pipe constructed of what appears to be Sch. 40, 1 1/2" pipe, with an O.D. of 1.900" and an I.D. of 1.610".

The muffler is constructed in such a manner that the cold air intake pipe enters through the left side of the chamber, and is concentric with the exhaust pipe, which exits through the right side of the chamber. In other words, the cold air intake pipe goes into the exhaust pipe. Exhaust enters the exhaust pipe by flowing around the outside of the air intake pipe. That is the only opening into the exhaust pipe, except for the inside of the cold air intake pipe. I hope that makes sense.

My math (always suspect) calculates the following areas:

Kohler exhaust port 0.86 sq. in.

Muffler inlet pipe 0.53

Exhaust outlet pipe (I.D.) 3.36 sq. in.

Cold air inlet pipe (O.D.) 2.84

Effective outlet area 0.52

The effective outlet area is represented by the xxxx's on the sketch.

These numbers concern me. The choking down of the exhaust ports into small diameter pipes doesn't seem like a normal way to design an exhaust system, and while the effective outlet area is only 0.01" less than the choked down exhaust inlet pipes, it still seems awfully small to me.

Beyond the design concerns, there is the manner of actual construction. As I noted earlier, the exhaust mounting flanges are poorly aligned with the 3/4" pipes, which will cause an additional restriction. Worse, the inside end of the cold air intake pipe doesn't look like it was ever cleaned up after being cut and before being welded into place.

The rough edges from the cut clearly increase the O.D. of that pipe, which in turn reduces the effective outlet area. The inside end of the exhaust outlet pipe may well have the same problem, but I have no way of seeing that point without tearing the muffler apart.

The thrust of all this boils down to this: I think these mufflers (at least the one on our PT-425) are choking the Kohler engines, and may be making them run hotter than necessary, and may be reducing available power to a significant degree.

I am seriously considering either modifying the muffler, building an entirely new one along the same design, but with different pipe sizes, or installing a Kohler muffler instead.

So, what do you all think?

SnowRidge