MinnesotaDaveChalmers

Platinum Member

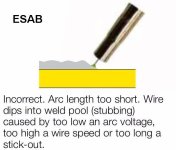

Yes but the same principal applies. Even with SMAW, There are three to four small zones where the voltage changes. I try to set my voltage to hit the sweet spot at about 3/8-inch stick out. To a degree if I want a hotter / more flowing puddle I'll open the stick out to say 1/2-inch. But if I go too far, say 3/4-inch, I'll run the risk of losing the arc. If I want a cooler / stiffer puddle I'll shorten the stick out to say 3/16 of an inch.

Same with SMAW, want a colder puddle jam the rod right into the puddle. Want a hotter more flowing puddle back the rod out some.

With self shielded T-8 wires, and dual shield most of those wires require 3/4 to 1 1/4-inch stick out.

Are you talking about running your engine drive with an Ln-25?

I've not run one so I can't say what it does.

I obviously agree with SMAW the arc voltage is adjusted by shortening/lengthening the arc.

But with a constant voltage power source I disagree with your description of FCAW.

Only my .02 - nothing more.